Tecam’s baghouse filters

Tecam’s baghouse filters

Tecam’s baghouse filters are custom-designed to offer highly efficient particle separation.

They are used in a wide variety of industrial processes in different sectors and with various products, including the automotive, petrochemical, chemical and mining industries and for products such as cement, plaster, iron, aluminium, ceramics, rubber and coal, among others.

They offer an alternative to electrostatic precipitators. Baghouse filters are suitable for collecting fly ash from low sulphur coal or fly ash that contains high levels of unburnt carbon.

Tecam’s tailor-made design

You can always count on tailor-made solutions with Tecam and, where necessary, the development of specific components, software and/or materials. Our technicians engage with every project, using their expertise and knowledge to design customised equipment for each case and customer.

No matter how big or complex the problem, Tecam is the technology partner that will provide you with the solutions you need at all times.

The advantages of Tecam baghouse filters

- The advantages of Tecam baghouse filters

- There are no moving internal parts.

- High levels of purification performance.

- Moderate energy consumption and pressure drop.

- They can be used on a wide variety of dust types.

- They allow for a modular design, meaning they can be used to treat a very wide range of gas flows.

What is a baghouse filter?

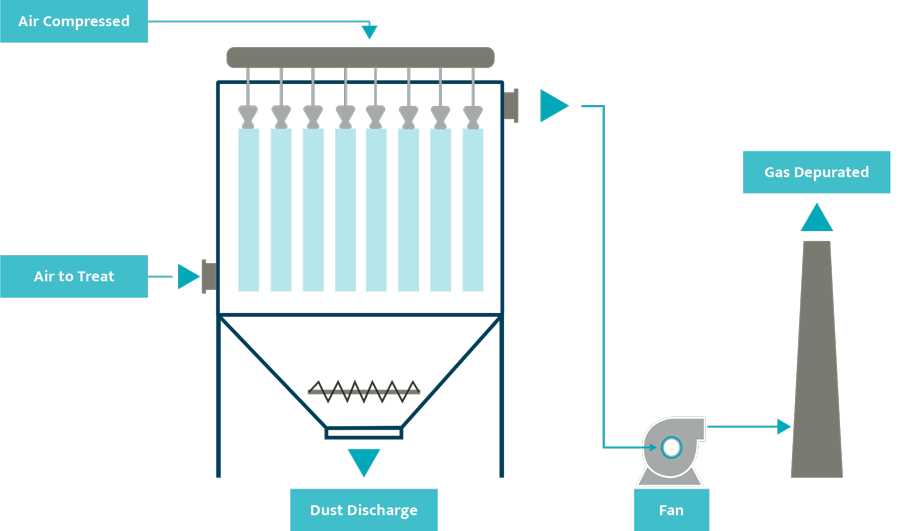

Baghouse filters are devices that remove the solid particles suspended in gas flows by passing the gas through fabric. They comprise rows of fabric “sleeves” that retain particles and are cleaned automatically by highly pressurised compressed air that is passed through them in a counter-current.

The particles transported in the airflow pass radially through the fabric sleeves and are deposited on the outside of them.

At certain intervals, which can be regulated in accordance with how dirty the fabric sleeves are, a counter-current of compressed air is passed through each sleeve so that the dust particles are detached from the fabric and fall onto the hopper below, where they are collected in order to be treated in the appropriate manner.

Specialists in the sectors that are most sensitive to environmental impacts

We drive sustainable productivity and innovation for industries with more extensive and more complex needs.