TECAM SCRUBBERS

GAS SCRUBBERS FOR ATMOSPHERIC EMISSIONS

Tecam’s scrubbers

Tecam’s gas scrubbers are designed to provide effective treatment for gas flows containing chlorinated compounds.

Scrubbers are used where there are concentrations of acid or basic gases, which are usually generated in conjunction with Volatile Organic Compounds (VOCs) containing halogenated compounds that generate acids.

They are recommended for use as purification systems for the specific elimination of the acid gas emissions (SO2) produced during the combustion of pollutants.

Tecam’s tailor-made design

You can always count on tailor-made solutions with Tecam and, where necessary, the development of specific components, software and/or materials. Our technicians engage with every project, using their expertise and knowledge to design customised equipment for each case and customer.

No matter how big or complex the problem, Tecam is the technology partner that will provide you with the solutions you need at all times.

The advantages of a Tecam scrubber

Neutralisation of pollutants in an atmospheric system and at ambient temperature.

They are highly efficient at eliminating pollutants, as they usually take the form of adsorption with acid-base neutralisation reactions that help to eliminate pollutants.

Scrubbers are ideal for treating odours.

Contact us

What is a scrubber?

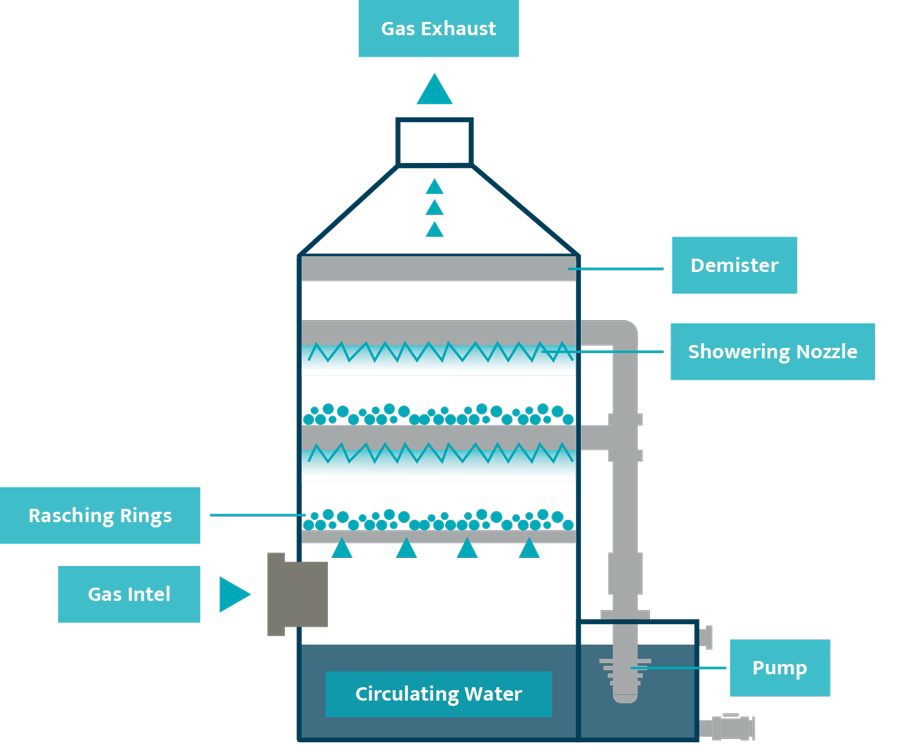

A scrubber is a system designed to treat gases that are emitted into the atmosphere. It is formed of a packed column where the contaminated gas is treated by exposing it to a liquid (usually in a counter-current) that adsorbs the pollutant. It is a non-destructive technology. In addition to the tower, the scrubber system also incorporates a column in which the adsorbent liquid and the gas to be treated are recirculated in a counter-current, as well as a recirculation pump to recirculate the adsorbent solution. Commonly, a collection tank is also installed, and at regular intervals the solution must be purged as the neutralised substances accumulate. Using a level control system, water and adsorbent fluid is then added in order to continue the adsorption process.

Because scrubber systems operate at ambient temperature, if the process gas reaches a high temperature (above 100 ºC – 150 ºC) it will need to be cooled. This is usually done by a device called a quench, which is located upstream of the scrubber. A quench consists of a non-packed column where the gas comes into contact with the neutralisation solution that will subsequently be used in the scrubber. This performs an initial neutralisation and also serves to cool the process gas.

Adsorption is a physical phenomenon in which the pollutant is diffused from the gas phase into the liquid phase. It is usually recommended for gases containing acidic pollutants (HCl, HF, H2SO4, etc.) or basic pollutants (NH3, etc.). For gases containing acidic pollutants, the liquid solution that is used acts as a strong base for the neutralisation. For gases containing basic pollutants, an acidic solution is used for the neutralisation.

When the air to be treated contains halogenated compounds, which are oxidised in an RTO or RCO, these compounds recombine with hydrogen to form the associated acid. In the case of chlorine (Cl), it combines with hydrogen to form hydrogen chloride (HCl). Consequently, at the outlet of the oxidiser it is necessary to install a scrubber containing basic adsorbent fluid, e.g. a caustic soda solution (NaOH).

How does a scrubber eliminate gases?

The contaminated gas is injected into the lower part of a column with a fixed bed. This bed serves to increase the area of contact between the contaminated gas and the adsorbent fluid. The adsorbent fluid must be suitable for the purposes of neutralising the pollutant in question.

The fluid is recirculated by a pump, which sends it up to the top of the column, from where it is then diffused onto the bed via a number of sprays. This ensures an even coverage.

This technology requires chemical reagents to neutralise the pollutants, which produces by-products (usually aqueous solutions containing salts) when the system is purged. These salts are not hazardous to the environment and can be transferred to the wastewater treatment system.

When to install a scrubber

Scrubbers are the ideal solution for cases where there are concentrations of acid or basic gases, which are usually generated in conjunction with Volatile Organic Compounds (VOCs) containing halogenated compounds.

They can also be used to treat odours.

Specialists in the sectors that are most sensitive to environmental impacts

We drive sustainable productivity and innovation for industries with more extensive and more complex needs.

Related news

Main environmental risks in tank storage terminals and how to mitigate them

Tank storage terminals represent a key element in the energy industry, as they provide a safe and efficient way to store and distribute petroleum-derived products and other hazardous liquids. However, they also entail a series of potential risks and threats to the...

Tecam has been awarded new VOC emissions abatement projects in China

Tecam continues to establish itself in the environmental project sector in Asia, with the awarding of 3 new projects for emissions removal in the Chinese market. Tecam, a leading supplier of environmental technology, announces that it has been awarded 3 new projects...

Technical services you should be looking for from your emissions abatement technology supplier

When it comes to finding the right emissions abatement technology supplier for your production plant, it is important to take into account the technical services you will be obtaining from them, such as preventive maintenance, etc. It is vital that your supplier...