TECAM ACTIVE CARBON FILTERS

Tecam’s active carbon filters

Tecam’s active carbon filters are principally designed to treat low concentrations of Volatile Organic Compounds (VOCs) or odoriferous compounds.

Active carbon filters have a wide range of applications. They can be used to control emissions in paint booths and to eliminate dioxins and furans generated during the incineration of solid urban waste (SUW), VOCs, H2S in biogas plants, NH3, amines, mercury vapour and acidic (lactic, acetic, muriatic) vapour, etc.

Tecam’s tailor-made design

You can always count on tailor-made solutions with Tecam and, where necessary, the development of specific components, software and/or materials. Our technicians engage with every project, using their

No matter how big or complex the problem, Tecam is the technology partner that will provide you with the solutions you need at all times.

What is an active carbon filter?

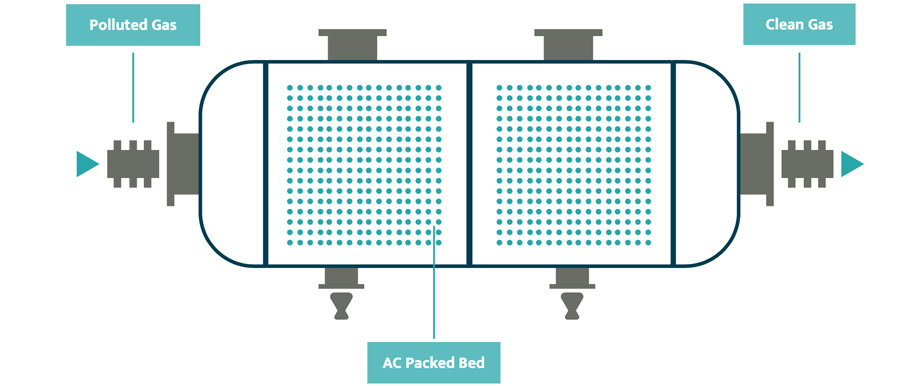

Active carbon filters are adsorption systems that capture and adsorb pollutants from the process gas, which adhere to the surface of the active carbon. The gas passes through a fixed bed of active carbon and adheres to the pores on the surface. The large transfer area per unit of volume facilitates the adsorption of the pollutant.

How does an active carbon filter work?

The contaminated gas passes through the carbon bed. As it passes through, the pollutants adhere to the surface of the filter, thereby cleaning the process gas. Consequently, over time the active carbon becomes saturated, and when it reaches its maximum adsorption capacity it must be desorbed in order to be used again. In order to avoid halting the process, two adsorption columns are normally used, of which one is performing adsorption while the other is undergoing desorption.

The advantages of active carbon filters

Active carbon filters are highly selective in terms of the pollutants they adsorb.

They are ideal for minimising Volatile Organic Compound (VOC) emissions in intermittent processes and for treating odours.

Specialists in the sectors that are most sensitive to environmental impacts

We drive sustainable productivity and innovation for industries with more extensive and more complex needs.