TECAM NOx ELIMINATION

SCR / SNCR

Tecam’s DeNOx systems

The DeNOx systems developed by Tecam are designed to reduce the emission of nitrogen oxides. We undertake tailor-made projects for each individual application, using

Tecam’s tailor-made design

You can always count on tailor-made solutions with Tecam and, where necessary, the development of specific components, software and/or materials. Our technicians engage with every project, using their

No matter how big or complex the problem, Tecam is the technology partner that will provide you with the solutions you need at all times.

The advantages of Tecam’s DeNOx systems

The main advantage of Selective Catalytic Reduction (SCR) is that it reduces NOx by up to 95 % without producing any polluting waste or by-products: it only generates (inert) nitrogen gas and water vapour. It operates at temperatures between 350 °C – 500 °C and can also be used on sources with a low concentration of NOx.

Selective Non-Catalytic Reduction(SNCR) systems offer lower costs in comparison to other technologies, as they require little space and minimal maintenance. They are easy to install and operate and work at high temperatures (850 °C – 1100 °C) without a catalyst. They can also process flows of residual gas with high levels of particulate matter (PM).

What is a DeNOx system?

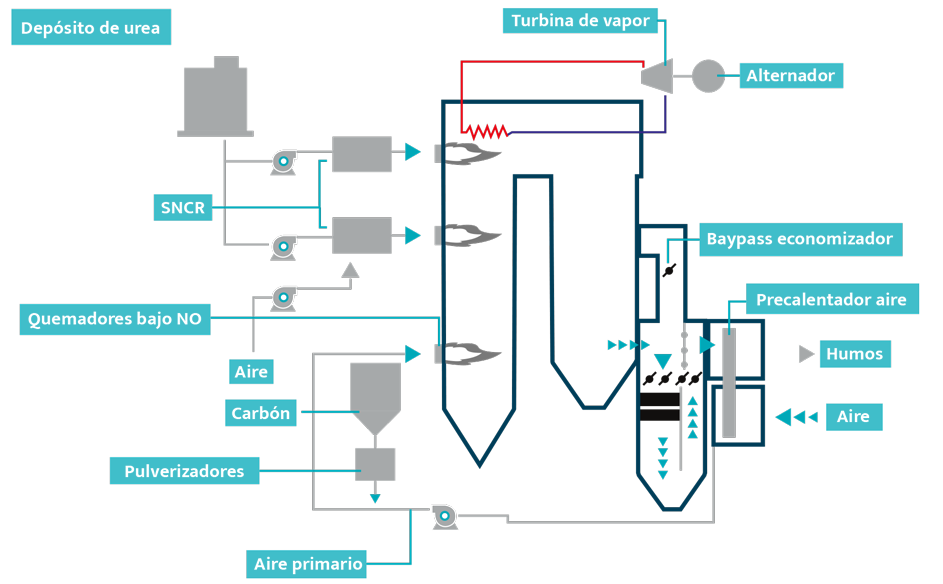

DeNox systems are used to reduce the amount of nitrous oxides present in gas flows. The solutions available include Selective Catalytic Reduction (SCR) systems and Selective Non-Catalytic Reduction (SNCR) systems.

Both types use an ammonia/urea-based solution to convert the NOx in the gas flow into N2 and water. Catalytic systems require a reactor, in which the reduction reaction takes place on a multi-layer porous catalyst bed. In non-catalytic systems, the gas to be treated must be heated to a high temperature (850 ºC – 1100 ºC) at the injection point.

Specialists in the sectors that are most sensitive to environmental impacts

We drive sustainable productivity and innovation for industries with more extensive and more complex needs.