Downloads

Tecam resources to help you improve environmental management in your company

Tecam provides you with materials and documentation on environmental technology so that you can download what you need at any time.

Our intention is to provide you with detailed information on existing environmental treatment trends and examples of use. You will also find Tecam’s corporate material in this section which will provide more knowledge of our services and possible applications in your business.

Brochures and catalogues

Tecam brochure.

Find out about our solutions (services and products) in the treatment of pollutant emissions and waste recovery. Tecam can do all this for you.

Tecam Tank Storage Brochure

Our Tecam environmental treatment solutions for the tank storage industry: specific products, special designs and integrated equipment.

Case Studies

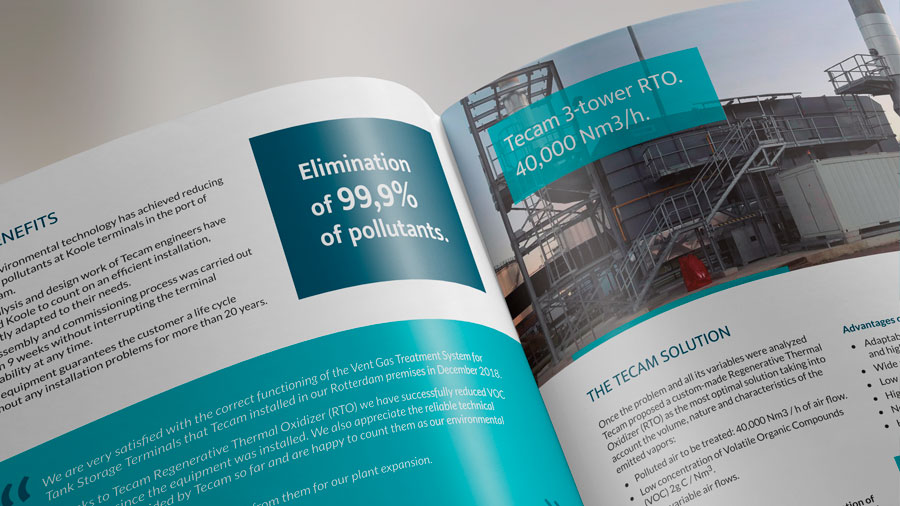

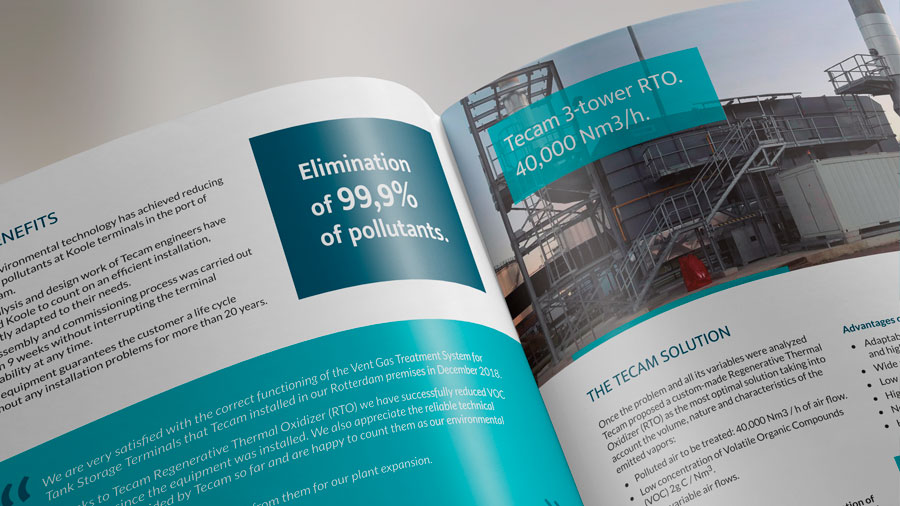

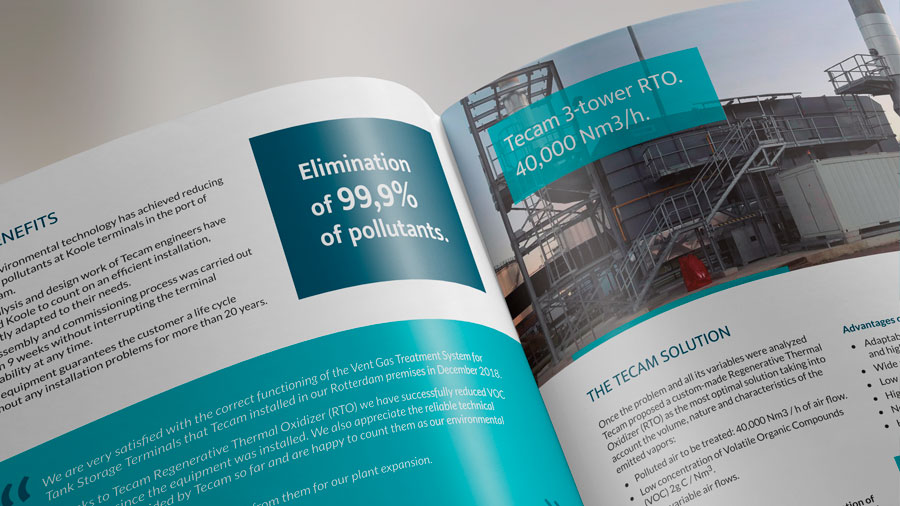

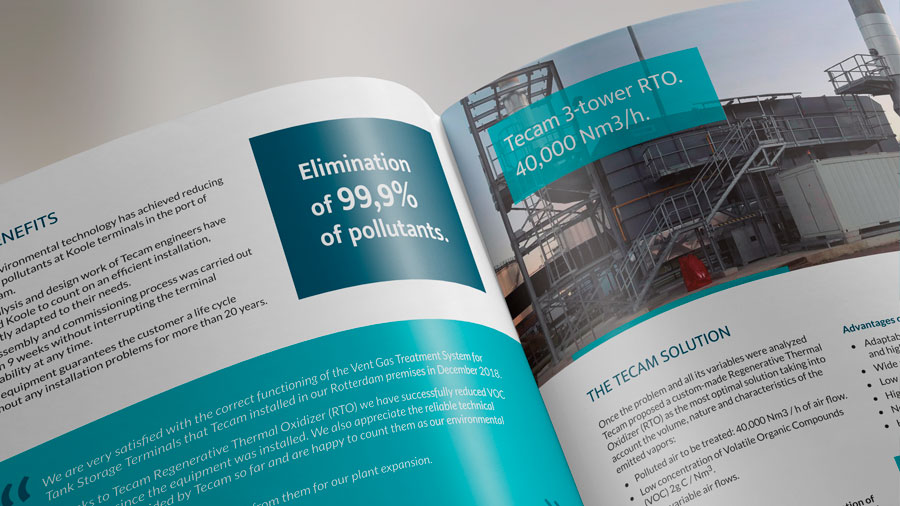

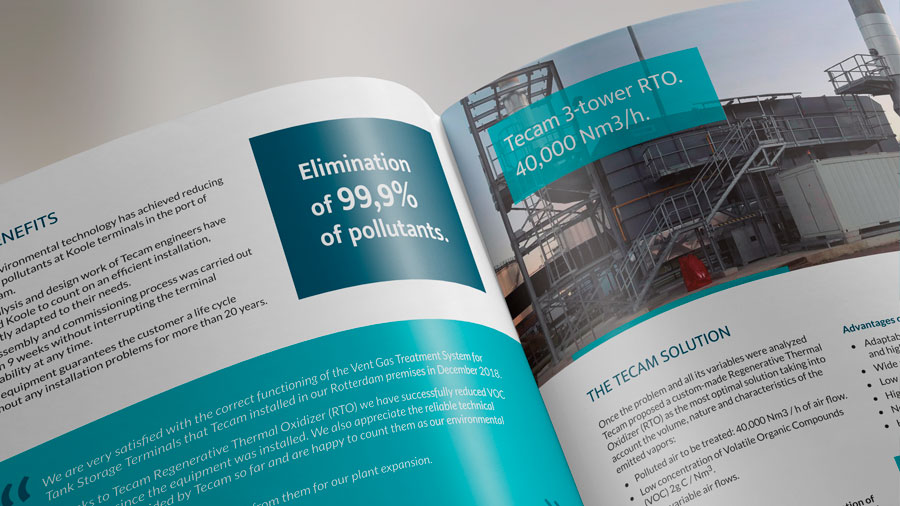

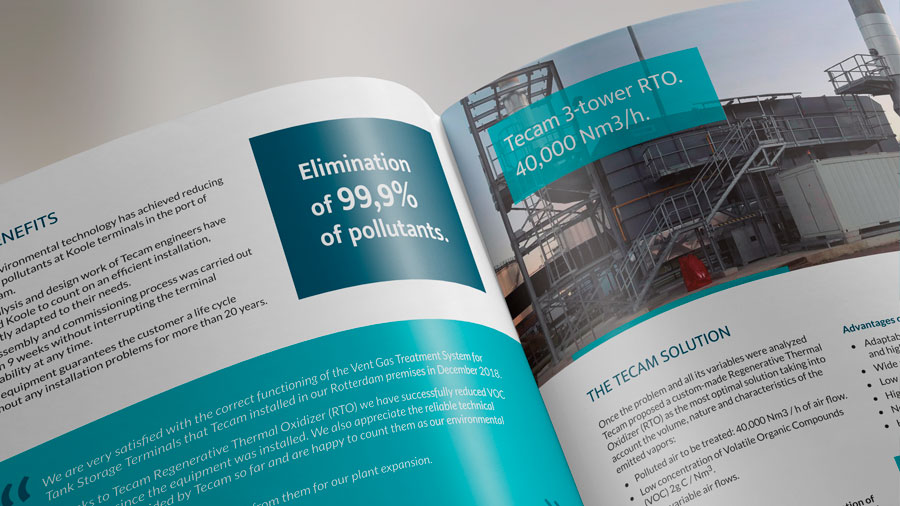

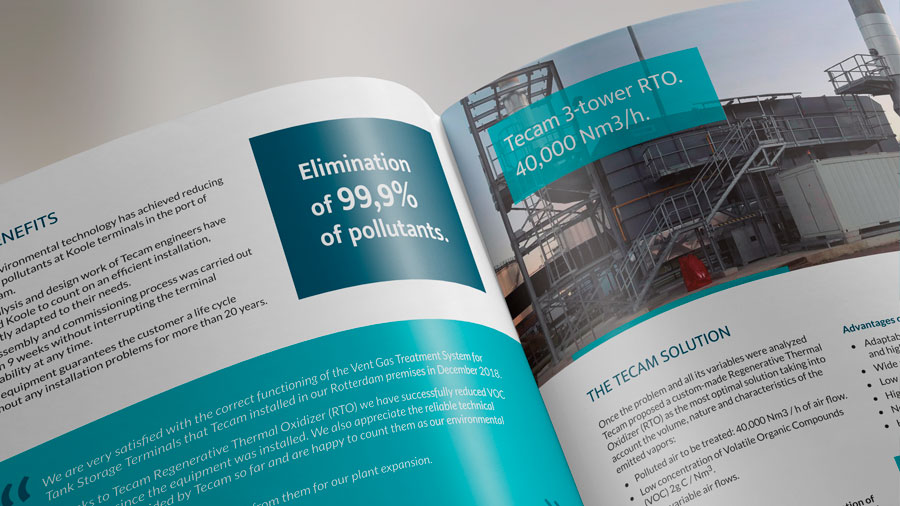

Case study | Koole Terminals

Tecam was contracted to reduce Volatile Organic Compound (VOC) emissions for the international hydrocarbon storage company Koole Tankstore Minerals at its facilities in the port of Rotterdam, the Netherlands.

You can download the success story here detailing the process and the result obtained.

Case Study | Oxiquim. Tank Storage.

Elimination of 99.9 % of VOC emissions generated during tank storage gas venting, and hydrocarbon recovery solution.

You can download the success story here detailing the process and the result obtained.

Case Study | Southern Packaging

Southern Packaging, LP is the leading plastic packaging manufacturer providing supply chain solutions to manufacturers around the world. Southern Packaging needed to eliminate the pollutant emissions that were generated during its rotogravure plant printing processes.

You can download the success story here detailing the process and the result obtained.

Case study | ADNOC

A worldwide unique facility. Tecam carried out the engineering and installation of a NORM (Naturally Occurring Radioactive Material) waste incineration plant together with a flue gas treatment system at ADNOC’s facility in the United Arab Emirates.

You can download the success story here detailing the process and the result obtained.

Case Study | Pharmaceutical production plant

This pharmaceutical company needed to eliminate the polluting emissions generated during the production processes at its plant and comply with the increasingly demanding environmental legislation.

You can download the success story here detailing the process and the result obtained.

Case Study | Casing manufacturing company

Elimination of corrosive polluting emissions in conditions of extreme humidity. This Tecam customer needed to treat the polluting emissions generated by its viscose production plant in Spain.

You can download the success story here detailing the process and the result obtained.

Case Study | Achieving Regulatory Compliance and

Sustainability: Tecam’s VOC Emissions Solution for Johnson Matthey.

Johnson Matthey faced a major environmental issue at their Royston facility, where the production processes were generating significant quantities of Volatile Organic Compounds (VOCs)—harmful pollutants that could contribute to air pollution and pose serious health risks. .

You can download the success story here detailing the process and the result obtained.

White Papers

White paper | 10 technologies for emissions treatment

In order to make your decision making easier, Tecam has compiled the characteristics, advantages and disadvantages of the “10 most demanded emission treatment technologies” in this document.

White Paper | Factors to consider when planning an emissions treatment project for your production plant

At Tecam we are convinced that environmental sustainability is the only viable path for the future of the industry. In the following White paper we try to highlight some of the most relevant factors when it comes to addressing the emissions treatment of our company.

White Paper | RTO recommended as BAT for chemical sector

In relation to exhaust gases, the chemical sector is a sector with high environmental risk.

In order to facilitate your decision-making process, at Tecam we have compiled in this document why Regenerative Thermal Oxidizers (RTO) are the most suitable technology to fully eliminate Volatile Organic Compounds (VOC) emissions at chemical production sites. And moreover, it is backed up by the European Commission’s Best Available Technique (BAT) document.

White Paper | Differences between RTO and TO technology

In order to facilitate your decision-making process, at Tecam we have compiled in this document the main differences between two of the main recommended technologies for VOC abatement: Regenerative Thermal Oxidizers (RTO) and Direct-Fired Thermal Oxidation (DFTO or TO).

White Paper | Factors to consider when planning an emissions treatment project for your Pharma production site.

In order to facilitate your decision-making process, at Tecam we have compiled in this document the main differences between two of the main recommended technologies for VOC abatement: Regenerative Thermal Oxidizers (RTO) and Direct-Fired Thermal Oxidation (DFTO or TO).

White Paper | How to eliminate emissions from wastewater treatment plants (WWTP) at pharma production sites.

Discover how your pharma production site can deal with WWTP emissions and comply with the strictest environmental legislation.

White Paper | Factors to consider when planning an emissions treatment project for the Oil & Gas sector.

Discover the aspects to consider when planning an emissions treatment project and comply with current and future environmental legislation.

White Paper | 10 Steps to Define an Optimized, Highly Efficient Strategy to Safely Eliminate Gaseous Emissions at Your Production Plant.

Discover the steps to consider when planning an emissions treatment project.

White Paper | Comprehensive Guide on Chemical Recycling.

Discover everything you need to know about Chemical Recycling through Pyrolysis.

White Paper | Current Challenges for Engineering Companies and How Tecam Provides Solutions

Discover how to mitigate the critical points inherent to Engineering Projects.